Introduction

The automotive industry is very complex. Now there are various reasons for its complexity, like, a great number of partners, from suppliers, producers, distributors to retailers and customers.

And also due to the large number of materials to manage like, unload, load, sorting, transfer, packaging, building of loading units, etc. for the same reasons the efficiency of these Operations decreases and the inventory and floor disruptions increases.

Sequential parts delivery minimizes this type of on site inventory, freeing up valuable floor space and cutting holding costs. Partnering with a top notch sequencing service providing company can play a crucial role in implementing such a setup.

like providing the sequencing, tracking, and delivery orchestration needed to make sequential parts delivery work effectively within complex automotive assembly lines.

What Is Sequential Parts Delivery?

Sequential Parts Delivery is a process where suppliers deliver parts in sequence to business as required. This process can also be referred to as in line vehicle sequencing(ILVS), sequential parts delivery(SPD), or just in sequence(JIS). It is a strategy used for lean manufacturing to reduce the need for standing inventory.

These methods are often supported by real time software which helps in synchronizing the delivery of the components. Companies use this data to check the stocks of inventory and to manufacture the parts before shipping them to the assembly line. The parts then arrive just in time(JIT) and in exact order as they are needed.

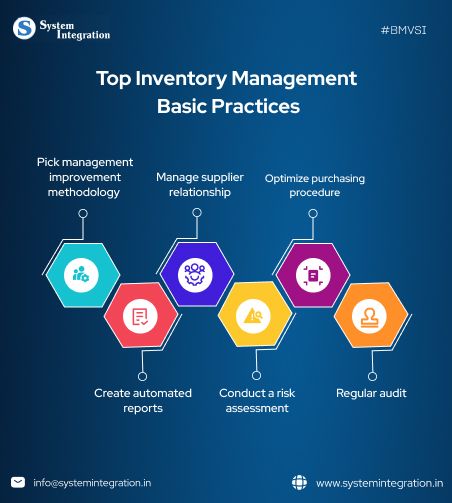

Why Is Inventory Management Important?

Inventory management is one of the major cost factors for any business. It makes sure that there is enough stock to meet the customer demands. If you check the balance sheet of any company, you will observe that inventory uses the major capital and current assets of the business.

Managing the inventory helps in cost minimization and avoids the over stocking. This reduces the expenses from storage and waste while enhancing the cash flow and boosting financial and operational performances.

- Cost Control

- Reduces holding costs

- Reduces waste

- Enhances cash flow

- Customer Satisfaction

- Make sure the product is available

- Higher customer trust and loyalty

- Operational Efficiency

- Streamlining processes

- Informs decision making

- Reduces the risk of over stocking

How Can Sequential Parts Delivery Help In Minimizing Inventory?

- Reduces On Hand Inventory Requirements

- Parts sequencing is prioritised and delivered when necessary, rather than being stockpiled.

- Cut down on overstock and buffer inventory.

- Aids in keeping lean inventory throughout the assembly line.

- Optimizes Warehouse & Floor Space

- Less inventory means more money and decluttered floor space.

- Reduces warehouse and production floor congestion.

- Allows Most storage space used for high value mission support rather than warehouses.

- Improves Material Flow Efficiency

- Reduces the number of touch points between storage units, parts only travel to point of use.

- Saves time finding, filing or carrying parts around the shop.

- Product Applications Provide problem free feeding of components.

- Minimizes Inventory Carrying Costs

- Reduces costs associated with storage, handling, insurance and capital tie up.

- Reduces the risks of obsolete stocks, damage and material ageing.

- Enhances Production Accuracy

- Because sequenced components decrease the likelihood of incorrect parts being stored or dispensed.

- Closer to just in time manufacturing.

- Forecasting inventory can be more exact when demand cycles are known.

- Supports Real Time Inventory Visibility

- Software enabled sequencing systems allow real time monitoring of parts in motion.

- Allows better replenishment meaning hoarding above need level becomes a thing of the past.

- Eliminates the need for time consuming and error prone manual inventory checks.

How Does SPD Help In Floor Disruptions?

SPD is a solution that introduces order, predictability and flow into shop floors which tend to be chaotic due to missing parts, having too much inventory or unexpected outages. Through accurately delivering the correct part, in the correct order, on time at every workstation SPD removes the causes of your typical floor upsets.

From an IT company perspective, a digital SPD solution is built using data in real time and system integration (ERP/MES/WMS) for automation to make material movement seamlessly. The result is a more error-proof, incorrect part placement-proof process that serves as an early alert system long before choke points occur.

- Key ways SPD minimises disruptions:

-

- Prevents Overcrowding & Clutter

- Minimises Search & Handling Delays

- Reduces Line Stoppages

- Synchronises Material & Production Flow

- Improves Operator Efficiency

Key Difference Between JIT And JIS Strategy

| Characteristics | JIT (just in time) | JIS (just in sequence) |

|---|---|---|

| Primary Focus | Delivering parts just in time | In time AND in correct assembling order |

| Safety buffer | Inefficient | Highly inefficient |

| Requirements for IT system | Integrated | Fully integrated |

| Stability of sequence | Irrelevant | Absolutely relevant |

| Downturn reaction times | Hours/days | Hours/minutes |

| Switching cost | High | Maximal |

The Role Of Digital Sequencing System

The Digital Sequencing System in today’s Sequential Parts Delivery is vital part of it which makes sure that at each workstation there are exactly the right parts at the time that are needed for assembling.

Without being limited by static schedules, it dynamically uses current data like the production schedule and barcode scans to sequence all parts in a correct sequence.

With a digital data of each part’s movement, between warehouse and assembly line, the system reduces inventory buildup, prevents the line stoppages and ensures there are no picking errors.

The Key Consideration In Implementing The SPD

Accurate Production Scheduling: The SPD based on time planning is relied upon for an accurate production forecast. The whole delivery series can be thrown into chaos by mistakes in the schedule.

Bill of Materials (BOM) Standardization: BOM data need to be coherent and synchronized across systems; otherwise you may end up with a wrong sequence, or missing parts because of tiny discrepancies.

Supplier Integration & Communication: Suppliers also need to have the ability to sequence, label and deliver parts as required. Clear SLAs and shared digital platforms are a must-have.

Barcode scan Traceability: Each part or kit should be readily traceable so that the correct item finds itself at the right workstation at the right time.

IT System Capability (MES/ERP Integration): demands tenacious system synchronization, order triggers, sequence data sharing, series real time status updates that cut through ERP, MES WMS and supplier portals.

Wrapping up

Sequential parts delivery minimizes the inventory and floor disruption. Partnering with a top notch sequencing service providing company can play a crucial role in implementing such a setup. With a digital data of each part’s movement, between warehouse and assembly line, part sequencing solution reduces inventory buildup, prevents the line stoppages and ensures there are no errors.

FAQs

Yes. They need to sequence, direct line and track (and also deliver supported by digital communication tools) parts exactly when you want them in production.

Most of the capital is invested in inventory. In addition, the company even has to pay for the storage and the cost of the goods and related staffing and other utilities to keep those items available. The inventory control aims and works on optimizing the inventory so you’re not overstocked or even out of stocks. It always keeps the inventory in check.

- Incorrect production scheduling

- Supplier delays or sequencing errors

- Inaccurate BOM data

- Bad floor plan etc by the away.

- No IT system integration in real time

By delivering components just in time/just in sequence in exact sequence, SPD eliminates the need for bulk storage at workstations and reduces the floor inventory.