Introduction

The semiconductor industry is the backbone of modern technology, powering everything from smartphones and electric vehicles to data centers and AI systems themselves. But as demand skyrockets and chip architectures become more complex, semiconductor manufacturers face an urgent challenge: how to optimize processes for higher yield, lower costs, and faster time-to-market.

This is where Artificial Intelligence (AI) is playing a game-changing role. By enabling smarter automation, predictive analytics, and real-time decision-making, AI is redefining semiconductor process optimization at every stage from design to wafer fabrication to testing.

Why Process Optimization Matters in Semiconductor?

Semiconductor manufacturing is one of the most complex and capital-intensive industries in the world. A single chip can require hundreds of process steps including deposition, lithography, etching, and testing. Even minor inefficiencies or defects can lead to:

- Yield losses

- Production delays

- Higher costs

- Supply chain bottlenecks

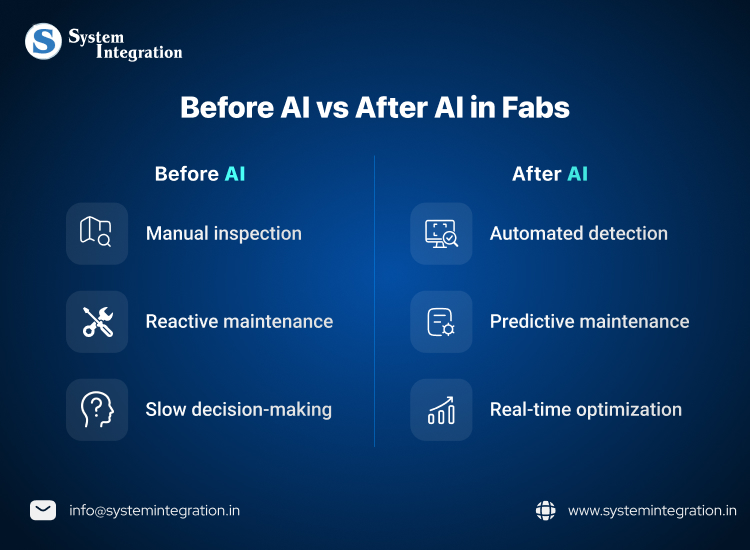

Traditional process optimization relies on human expertise, historical data, and rule-based methods. While effective, these approaches struggle to keep up with the scale and variability of modern chipmaking.

AI changes this by enabling data-driven, adaptive, and predictive optimization.

AI Applications in Semiconductor Process Optimization

a) Yield Improvement through Predictive Analytics

AI models can analyze process data to predict yield outcomes before wafers complete production. Machine learning algorithms identify subtle correlations that humans might miss, allowing manufacturers to adjust recipes and prevent yield losses.

✅ Example: Predicting which wafers are at high risk of failure based on tool parameters, enabling corrective actions early.

b) Defect Detection with Computer Vision

High-resolution wafer inspection generates massive image datasets. Traditionally, defect detection required manual classification or rule-based software. AI-powered computer vision models can now detect microscopic defects with higher speed and accuracy.

✅ Result: Reduced false positives, faster root cause analysis, and improved overall quality.

c) Process Control and Automation

AI can monitor equipment sensors in real time and make automated adjustments to process parameters. This reduces variability and ensures more consistent output.

✅ Example: Real-time AI-driven tuning of etching or deposition conditions to maintain uniform wafer quality.

d) Predictive Maintenance of Fab Equipment

Downtime in a semiconductor fab can cost millions of dollars per hour. AI-driven predictive maintenance uses sensor data and historical patterns to forecast when equipment is likely to fail.

✅ Benefit: Reduced unplanned downtime, extended equipment life, and higher overall productivity.

e) AI for Design-to-Manufacturing Integration

AI bridges the gap between chip design and fabrication by simulating how design choices impact manufacturing complexity. This ensures designs are optimized not just for performance, but also for manufacturability.

✅ Outcome: Faster design cycles and reduced re-spins.

f) Supply Chain Optimization with AI

Beyond the fab, AI helps semiconductor companies manage their supply chains more effectively by predicting demand, optimizing logistics, and mitigating disruptions.

✅ Benefit: Reduced inventory costs and faster delivery cycles.

Benefits of AI in Semiconductor Process Optimization

- Higher Yield and Reduced Defects

AI enables manufacturers to detect hidden patterns in process data and wafer images, which helps in identifying potential defects much earlier. This proactive approach reduces scrap, increases yield, and ensures more reliable chips reach the market.

- Faster Time-to-Market

With AI-driven real-time decision-making, fabs can adjust process parameters during production instead of waiting for post-production analysis. This shortens production cycles and accelerates time-to-market for new semiconductor products.

- Cost Reduction and Resource Optimization

AI helps manufacturers optimize the use of raw materials, energy, and chemicals, leading to lower operational costs. By tuning process recipes for efficiency, fabs can save resources without compromising product quality.

- Enhanced Equipment Performance

Through predictive maintenance, AI monitors the health of manufacturing equipment and forecasts potential failures before they occur. This reduces unplanned downtime, prolongs equipment lifespan, and ensures uninterrupted operations.

- Scalability for Complex Chip Architectures

As chip designs move toward smaller nodes like 5nm and 3nm, process complexity increases significantly. AI systems can adapt to these evolving architectures, making scaling smoother and more efficient.

- Better Decision-Making with Data Insights

AI analyzes the enormous volumes of data generated by semiconductor fabs to deliver actionable insights. Engineers can use these insights to identify root causes of issues, optimize process parameters, and make more consistent and data-backed decisions.

- Sustainability and Green Manufacturing

By minimizing energy consumption, chemical usage, and defective wafer production, AI contributes to more eco-friendly semiconductor manufacturing practices. This aligns with global sustainability and ESG (Environmental, Social, and Governance) goals.

Challenges and Considerations

- Data Quality and Availability

AI requires large volumes of accurate and clean data to function effectively. However, in many fabs, data is fragmented, noisy, or stored in isolated systems, which makes it difficult to train reliable AI models.

- Integration with Legacy Systems

Semiconductor fabs often use equipment and control systems that have been in place for decades. Integrating modern AI technologies with these legacy systems can be costly and technically challenging.

- High Initial Investment

Deploying AI solutions involves significant upfront costs, including infrastructure, advanced computing resources, and skilled personnel. Smaller fabs may find it difficult to justify this investment in the short term.

- Shortage of Skilled Workforce

There is a growing need for professionals who possess expertise in both semiconductor engineering and artificial intelligence. The current shortage of such hybrid-skilled workers poses a barrier to AI adoption.

- Cybersecurity and Data Privacy Risks

AI-driven fabs rely heavily on connected systems, which increases their vulnerability to cyberattacks. Protecting sensitive design and process data from breaches is a major challenge for manufacturers.

- Lack of Model Transparency

AI models often operate like “black boxes,” providing decisions without clear explanations. In semiconductor manufacturing, where precision is critical, this lack of explainability can make engineers hesitant to trust AI recommendations.

- Need for Continuous Model Updates

Since semiconductor processes evolve rapidly, AI models trained on outdated data can quickly lose relevance. Regular retraining and model updates are required, which demand ongoing investment in data management and AI infrastructure.

“AI doesn’t just improve semiconductor processes—it redefines them, turning fabs into self-learning systems.”

Future Outlook: AI-Powered “Smart Fabs”

The next generation of semiconductor fabs will be AI-first environments with intelligent process control, fully automated defect detection, and real-time optimization. AI agents will continuously learn from data, making fabs self-optimizing ecosystems.

Coupled with edge AI and quantum computing, the future of semiconductor manufacturing promises:

- Hyper-efficient fabrication

- Near-zero downtime

- Faster innovation cycles

Conclusion

AI is no longer a support tool but a core driver of semiconductor process optimization. From improving yields to reducing downtime and enabling smart fabs, AI is helping the semiconductor industry meet growing global demand while tackling cost, complexity, and sustainability challenges.

Companies that embrace AI-driven process optimization today will have a decisive competitive edge in the semiconductor race of tomorrow.

FAQs

Traditional methods rely on rule-based systems and manual expertise, while AI leverages real-time data, predictive models, and adaptive learning for smarter decision-making.

Machine learning algorithms analyze process and sensor data to predict yield outcomes and detect patterns that cause defects, allowing proactive adjustments.

Not yet. While AI automates many processes (inspection, tuning, maintenance), full automation requires further advancements in robotics, interoperability, and AI integration.

Key challenges include ensuring high-quality data, integrating AI with legacy fab equipment, workforce training, and addressing cybersecurity concerns.

Major players like Intel, TSMC, Samsung, and ASML are investing heavily in AI-powered fabs and process optimization.