Introduction

In a world increasingly driven by AI adoption, automation, robotics, and data intelligence, supply chains are evolving at unprecedented speeds. But a pressing question looms large across boardrooms:

Are supply chains truly ready for an autonomous future?

From AI powered decision making to robotic warehouses, the promise of autonomy suggests more efficient, resilient, and scalable operations. Yet the road to this future is far from straightforward, filled with gaps in technology readiness, workforce transformation needs, data challenges, and strategic investments.

What Does An Autonomous Supply Chain Really Mean?

An autonomous supply chain refers to systems and processes that can operate, adapt, and respond to changes with minimal human intervention using technologies like:

→ Artificial intelligence (AI) and agentic AI

→ Machine learning (ML)

→ Robotics & autonomous robots

→ IoT sensors

→ Predictive analytics

In such systems, decisions, such as rerouting shipments, adjusting inventory levels, and predicting demand, are handled by intelligent platforms that continuously learn from data and real-time inputs.

However, autonomy isn’t just automation on steroids. It means intelligent, self-learning systems that behave proactively, not just reactively.

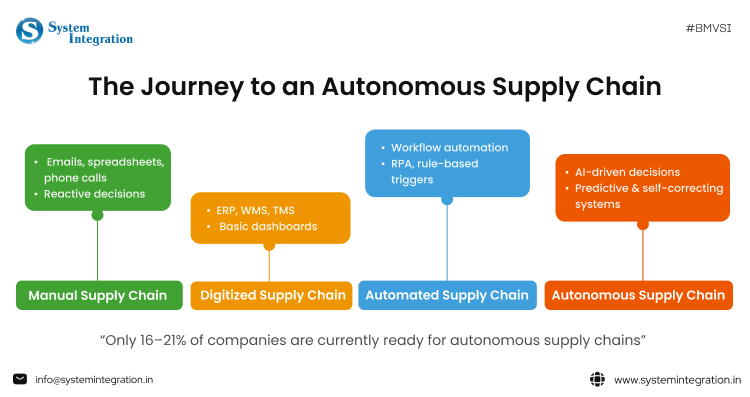

How Far Along Are Supply Chains Today?

Despite rising investments in automation and AI, research shows that Full Autonomy Remains a Distant Goal:

Key Readiness Stats:

- Only 21% of manufacturers say they are fully prepared for AI adoption revealing significant data and integration gaps.

- According to a major industry report, the median maturity for autonomous capabilities is just 16%, suggesting most organizations are still early in the journey.

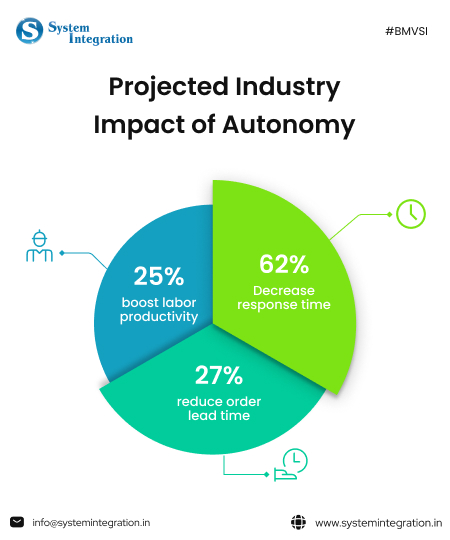

- Even though 75% of manufacturers expect AI to be a top contributor to operating margins by 2026, few are ready to deploy it comprehensively.

These figures show that the vision of a fully autonomous supply chain exists, but most enterprises are still laying the digital groundwork.

Autonomy Impact: Before Vs After

| Traditional | Autonomous |

|---|---|

| Reactive planning | Predictive planning |

| Manual routing | Dynamic route optimization |

| Inventory guesswork | AI demand forecasting |

| High human dependency | Human oversight only |

Real-World Autonomous Supply Chain Use Cases

- Case Study 1:

Amazon’s Robotics NetworkAmazon has deployed hundreds of thousands of robots in its logistics hubs to speed sorting, packing, and inventory movement, demonstrating how automation scales modern warehouses.

[Source: Financial Times] - Case Study 2: Walmart & Symbotic Partnership

Walmart’s multi-year deal with Symbotic aims to automate pickup and delivery centers across thousands of stores, leveraging AI and robotics for faster, more reliable fulfillment.

[Source: The Sun] - Case Study 3: FedEx and Autonomous AI

FedEx has invested in autonomous logistics platforms to streamline fulfillment and inventory processes, illustrating how carriers are aligning with AI advances.

[Source: Reuters] - Case Study 4: AI Decision Support Tools

Next-gen AI platforms use real-time data to detect demand shifts, recommend optimized routes, and predict supplier risk unlocking intelligence that was impossible with legacy systems.

[Source: StartUs Insights]

What’s Holding Supply Chain Back From Full Autonomy?

Even with growth and innovation, significant barriers stand in the way:

- Data Challenges

Poor data quality and fragmented systems cripple advanced AI capabilities. Many organizations lack unified platforms that can power autonomous decision engines. - Workforce Skills Gap

Adopting autonomy demands new skills from data scientists to AI engineers leaving many organizations underprepared. - Legacy Systems

Old ERP and supply chain systems don’t always communicate, making seamless automation difficult. - Trust & Cultural Resistance

Supply chain leaders often hesitate to let autonomous systems make high-impact decisions without human validation especially in volatile environments.

So, Are We Ready Yet?

The honest answer: Not quite, but the journey is underway.

Most supply chains are on a spectrum of automation from basic RPA and warehouse automation to pilot AI forecasting models. But full autonomy is still emerging.

Here’s how experts see the path ahead:

→ Incremental implementations → starting with narrow, high-ROI tasks

→ Hybrid human-AI models→ humans manage exceptions and strategic decisions

→ Investment in data foundations→ master data management is key

This hybrid future ensures machines and humans complement each other’s strengths not replace them.

Conclusion

Supply chains are evolving toward autonomy, but readiness varies widely. While pilot projects and robotics deployments are growing, full autonomy will require investment, cultural change, and a layered approach to AI adoption.

The future isn’t distant, it’s unfolding now and businesses that prepare today will be tomorrow’s industry leaders.

How BMVSI Enables Autonomous Supply Chain Automation?

At BMVSI, we understand that supply chain autonomy isn’t a switch you flip, it’s a journey you design. Our approach focuses on helping organizations move from fragmented, manual operations to intelligent, AI-driven and automation-ready supply chains, without disrupting existing systems.

We build custom supply chain automation solutions that integrate seamlessly with ERPs, WMS, TMS, and third-party platforms enabling real-time visibility, automated decision workflows, and predictive insights. From AI-powered demand forecasting and inventory optimization to workflow automation, agentic AI systems, and data intelligence layers, BMVSI helps businesses reduce operational friction while increasing speed, accuracy, and resilience.

Whether you’re just beginning with automation or preparing for advanced autonomous capabilities, BMVSI acts as your technology and strategy partner, ensuring your supply chain doesn’t just keep up with the future, but leads it.

FAQs

An autonomous supply chain uses AI, machine learning, data analytics, and robotics to make integrated decisions and self-optimise processes with minimal human input.

Most experts predict significant adoption within the next 5–10 years. Full lights-off autonomy, meaning no human involvement, is not expected soon, but hybrid human-AI models are already emerging.

Enhanced operational efficiency, better visibility, faster response times, reduced costs, improved forecasting, and stronger resilience against disruptions.

Key challenges include poor data quality, legacy systems, workforce skills gaps, cybersecurity risks, and cultural resistance to replacing human decisions.

Yes, but start small. Invest in scalable automation and AI tools that improve specific functions (like demand planning or warehouse robotics) while building data foundations.