Introduction

Let’s be honest, if manufacturing in 2026 was a movie, AI Automation would be the main hero, machines would be the supporting cast, and humans would be the smart directors making everything work in harmony.

But here’s the twist, not every factory is ready for that blockbuster role yet. Some are still printing job sheets, updating production logs manually, and relying on uncle Sharmaji’s “gut-based forecasting”. (Respect for his experience…butdata might do a better job, just saying 😉)

AI-driven manufacturing isn’t the future anymore. It’s the present walking straight toward 2026 with a tool kit, saying “Move aside, let me automate that.”

So the big question is….

In this blog, we’ll break down what AI-readiness means, how to assess your current position, what gaps you need to fill, and how to move towards automation the smart way not the “but robots first, find use case later” way.

Why AI Automation In Manufacturing Is No Longer Optional In 2026

Traditionally, factories relied on manual supervision, static processes, and experience-based decisions. But global manufacturing is now driven by:

✔ Just-In-Time delivery

✔ High customization expectations

✔ Low downtime tolerance

✔ Rising labor cost

✔ Global competition

✔ Data availability

Customers want better quality, faster deliveries, less defects and competitive pricing.

The only way to achieve all four simultaneously is AI Automation.

Here’s what AI can do for your manufacturing plant:

- Track machine health 24/7

- Predict failures weeks before they occur

- Prevent downtime proactively

- Optimize energy consumption

- Reduce human error in checklist processes

- Automate approvals, job cards, QC reports

- Identify defects with computer vision faster than the human eye

- Forecast inventory needs & demand cycles

- Train workers using generative AI manuals

In short, AI doesn’t replace humans; it replaces inefficiency. A factory using AI is like a manager with 500 extra brains working quietly in the background.

If you’re thinking “wow, this sounds expensive”, remember what’s more expensive: A breakdown in peak season, rejection batches, manual errors, and delay penalties.

AI Automation Readiness: Are You Future-Ready Or Future-Scared?

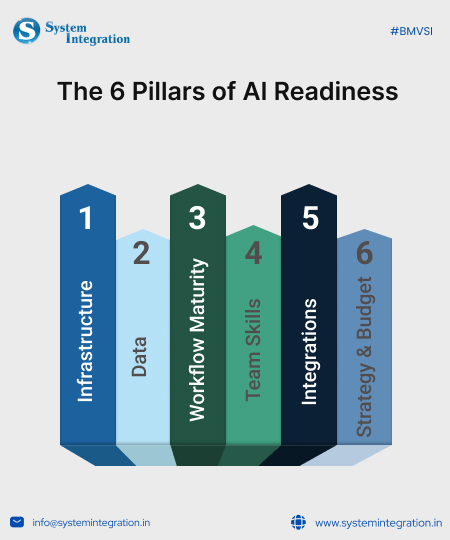

AI Readiness = Infrastructure + Data + Skilled Workforce + Process Maturity + Integrations

| NOT READY MEANS | READY MEANS |

|---|---|

| Spreadsheets everywhere | Data is collected, structured, and accessible |

| Production data unavailable or stored in someone’s head | Machines and software speak to each other |

| Machines working fine but ‘blind’ | Teams understand digital workflows |

| Manual approvals & follow-ups eating productivity | You know what to automate first |

| No automation Roadmap | ROI from automation is measurable |

Let’s evaluate how ready you are.

- Data Infrastructure: AI Runs on Data, Not Wishes

Do you have:- Machine production logs?

- Quality defect records?

- Maintenance history?

- Energy consumption data?

- Order timelines, delivery times, wastage logs?

If this data exists ONLY in someone’s brain or Excel file named “final_final_NEW_version2.xlsx”, we have work to do.

To be AI ready:

-

- Move from paper → digital logs

- Implement ERP/MES

- Standardize data capture

- Integrate all production data on a central system

AI cannot optimize chaos. It thrives on organized information.

- Workflow Automation: Are Tasks Automated or Human-Dependent?

Think about:

-

- Maintenance work orders

- Inventory reordering

- Quality check approvals

- Daily production reporting

- Purchase approval workflows

If most require phone calls, back-and-forth messages or chasing people around with “bhai woh file de de” – You need automation.

Automation tools to begin with:

-

- N8n

- Make.com

- Zapier

- RPA tools

- Custom automation workflows

Even small automations can save thousands of man-hours yearly.

- Machine Connectivity: Can Machines Talk to Systems?

Machines must share data through:

-

- IoT sensors

- PLC integrations

- OPC UA/MQTT protocols

- Cloud connectivity

- Retro-fit sensors for old machines

Without machine data, AI remains blind.

- Workforce Readiness: Humans + AI = SuperTeam

AI doesn’t fire people.

It upskills them into higher-value roles.

Employees need training on:

-

- Dashboards

- AI-assisted decisions

- Using digital work instructions

- Cobot collaboration

- Understanding predictive alerts

The goal is not “replace people” but remove repetitive work. Imagine giving your team their time back, unproductive chaos – eliminated.

- Cybersecurity & Compliance

More connectivity = more vulnerability if not secured.

Implement:

-

- Network security policies

- Role-based access control

- Regular data backups

- Industrial firewalls

- Compliance frameworks

Nobody wants a hacker controlling conveyor belts like a video game.

How To Assess Your AI Automation Readiness For 2026 (Self-Evaluation Checklist)

Score yourself from 1 to 5 each.

| Stage | Element | Score |

|---|---|---|

| Digital Infrastructure | ERP, MES, IoT, Cloud Adoption | ?/5 |

| Data Maturity | Data Accuracy, Accessibility & Usability | ?/5 |

| Automation Level | Manual vs Automated Workflows | ?/5 |

| Team Skills | AI Literacy, Training, Adaptability | ?/5 |

| Integration Capability | Systems talking to each other | ?/5 |

| Vision & Strategy | Clear Roadmap for AI Adoption | ?/5 |

Score 22-30 → You’re ready for AI (like Iron Man with Jarvis)

Score 15-21 → You’re on the right route.

Below 15 → Start Small, one workflow at a time.

The 2026 AI Adoption Roadmap (Step By Step Plan)

Phase 1 —> Digital Foundation

- Move from paper to digital systems

- Start using ERP, MES, CMMS

- Collect structured machine & production data

Phase 2 —> Basic Automation

- Create workflow automations

- Auto-trigger maintenance tasks

- Automate reporting & alerts

- Integrate machines & sensors gradually

Phase 3 —> AI & ML Integration

- Predictive maintenance AI models

- AI-based defect detection

- Predictive demand planning

- Autonomous scheduling

Phase 4 —> Smart Factory Operations

- Real-time dashboards

- AI-decision recommendations

- Energy optimization

- Production line adjustments on the fly

Phase 5 —> Industry 5.0

- Human-machine collaboration

- Cobots & autonomous logistics

- Digital twin simulations

- Self-optimizing systems

This transformation is not one giant step but a journey of agile upgrades.

Real Use Cases To Understand AI-Powered Manufacturing

AI Automation isn’t just theory, it’s already transforming factory floors. Here are practical examples of how modern plants are applying it today:

1. Production Sequencing & Scheduling Automation (Our Real Use Case)

(A powerful example of AI automation implemented by System Integration).

A manufacturing unit was struggling with:

- Manual job sequencing on Excel sheets

- Last-minute rescheduling chaos

- Machine idle time increasing cost

- Dependence on planners for decisions

- Limited visibility of live production flow

We built a Sequencing Automation Software that:

- Automatically sequences jobs based on logic & priority

- Suggests optimal machine allocation

- Ensures balanced load distribution

- Enables real-time rescheduling

- Improves throughput & reduces planning time

- Gives a complete visibility dashboard

Result?

- Planning that once took hours now became a few clicks, with higher accuracy & faster execution.

- No more whiteboard wars. No more “final_planning_v7.xlsx” versions.

2. Predictive Maintenance

- Instead of waiting for a breakdown, AI predicts failure 15-30 days earlier.

- Maintenance is planned, downtime is avoided, spare parts are pre-arranged.

- No more “machine stopped, team panic & production halted” mornings.

3. AI Visual Quality Inspection

- Cameras + AI = detect defects in milliseconds.

- Ideal for automotive, textile, electronics, FMCG.

AI sees what tired eyes miss even tiny scratches get exposed like a crime scene zoom-in shot.

4. AI Demand & Inventory Forecasting

- No more panic-purchasing or surprise shortages.

- AI predicts demand, stocks inventory smartly, reduces carrying cost & speeds delivery.

- Perfect for plants juggling SKUs like a circus.

5. Digital Twin Factory Simulation

- A virtual copy of your factory that tests scenarios before you execute them in real life.

- Want to try new shifts, new layout or extra line?

- Simulate → see outcome → decide confidently → avoid expensive mistakes.

Benefits Of Being AI Ready In 2026

→ 30–50% reduced downtime

→ 20–35% higher productivity

→ Better resource planning

→ Lower quality rejections

→ Faster production cycles

→ Higher margins & ROI

→ And yes, zero stress about last-minute customer demands.

AI doesn’t panic. Humans do. AI just calculates.

Cost & ROI: Is It Expensive? (Only Of Delayed)

A huge misconception is “AI is too costly for us.”

But manufacturers waste more money yearly on:

- Downtime

- Rejects & faulty production

- Unplanned stoppages

- Manual errors

- Delayed decisions

Even a 5% improvement in OEE = huge profit uplift.

AI typically pays itself back within 6–18 months.

Invest once → optimized forever.

Conclusion: Is Your Manufacturing Unit Ready?

AI automation is not a luxury in 2026, it’s survival.

Manufacturers that prepare now will:

✔ produce faster

✔ cut costs

✔ reduce downtime

✔ scale like crazy

✔ stay ahead of competition

Those who delay will be trying to catch up with companies already running AI-powered plants.

So ask yourself honestly:

“Are we AI-ready or still stuck in manual chaos?”

If the latter, good news, starting today means you’re not late.

Just earlier than the rest.

Many forward-thinking companies are already taking their first step by modernizing processes, automating workflows and implementing systems like job sequencing tools, IoT-based monitoring & AI-driven planning. That’s exactly where solutions built by us (BMV System Integration) have been making a difference helping manufacturers transition smoothly from manual to automated without disrupting ongoing operations.

FAQs

AI automation uses machine learning, IoT, predictive analytics and workflow automation to optimize production, reduce downtime and enable smart factory operations.

Not necessarily. AI gives ROI within 6–18 months by reducing breakdown losses, rejections and speeding workflow. Delaying costs more.

No. Even old machines can be connected using retro-fit IoT sensors & PLC integration.

AI replaces repetitive work, not people. Teams shift to higher value roles like monitoring, strategic decision-making & supervision.

Digitization + data collection. Start with ERP/MES and automate one workflow at a time.

Use the AI Readiness Score framework in this blog (0–30 scale). Score 22+ means ready for automation.

Yes. We help manufacturers adopt workflow automation, production sequencing, IoT integration & AI models at a scalable pace.